As a non-destructive method for investigating the elemental and moreover chemical composition of surfaces (information depth: a few nanometres) of solid materials such as bulk solids, powders and thin films, X-ray Photoelectron Spectroscopy, XPS, can be used both qualitatively and quantitatively. In addition to the elemental composition (element-dependent detection limit is approx. 0.1-1 at-%), oxidation states of the elements and in many cases also chemical compounds can be distinguished.

Briefly, XPS is based on the analysis of the kinetic energy of photoelectrons, i.e. electrons that are excited and ejected by X-rays, which show element- and orbital-specific binding energies. The high surface sensitivity of the method, in contrast to other techniques such as EDX (energy dispersive X-ray spectroscopy) in electron microscopy, results from the much smaller inelastic mean free path length (IMFP) of these photoelectrons in the sample.

Instrument

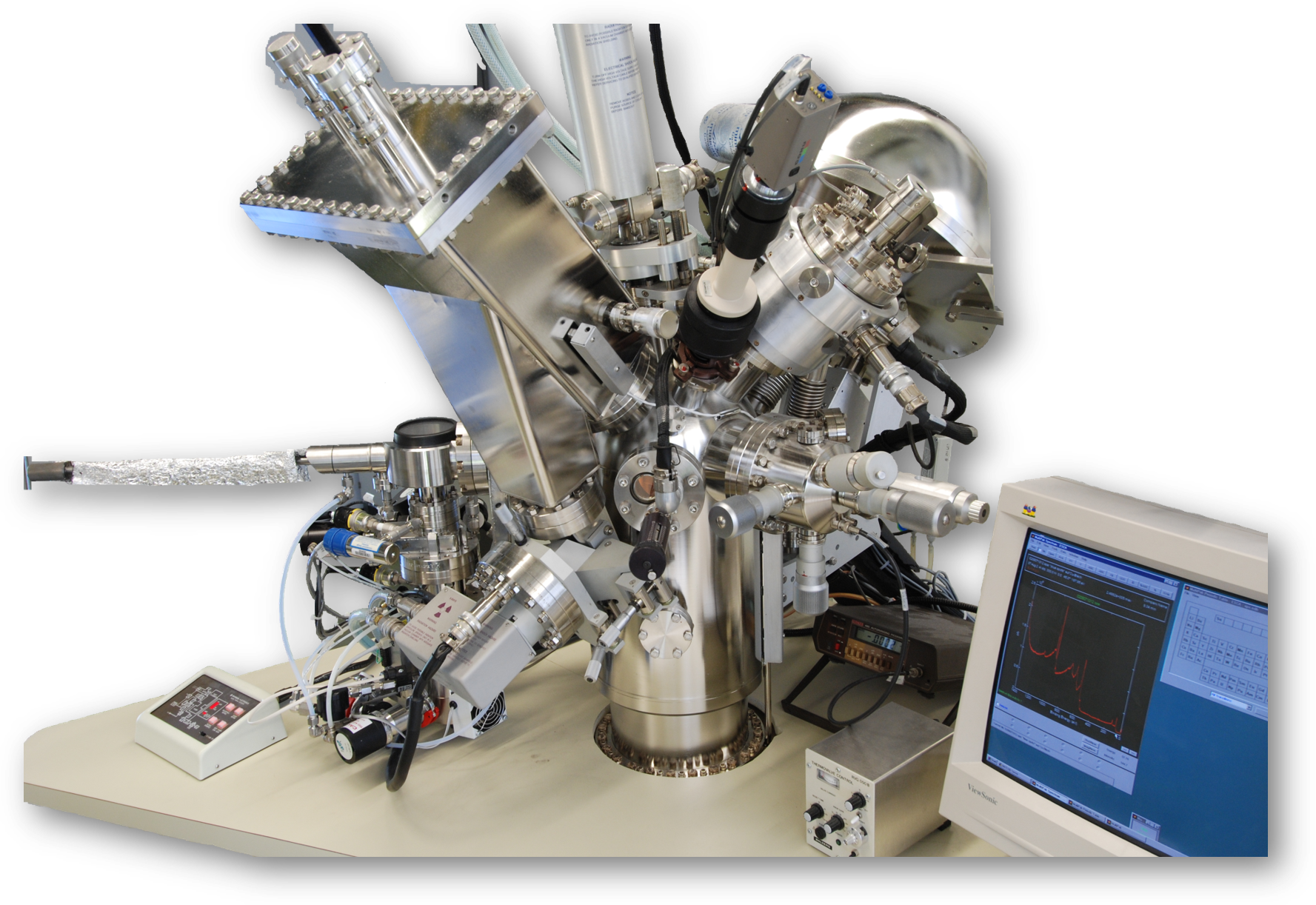

X-Ray Photoelectron Spectrometer

PHI 5800 ESCA System (47.0.211)

Commercial Physical Electronics 'PHI 5800 ESCA System'

X-ray Sources

- Monochromatic Al-Kα

- Al/Mg Kα dual anode

Sample Neutralisation

- BaOx-cathode for charge compensation on semiconducting or insulating samples

Depth Profiling

- Ar+ ion source ('sputter gun') for depth profiling on samples (< 1 µm)

Sample Specifications

- Solid samples

- Bulk solids: measured as-received

- Powder samples: deposited on a conductive carbon pad

- Outgassed and dry (measurement under UHV conditions)

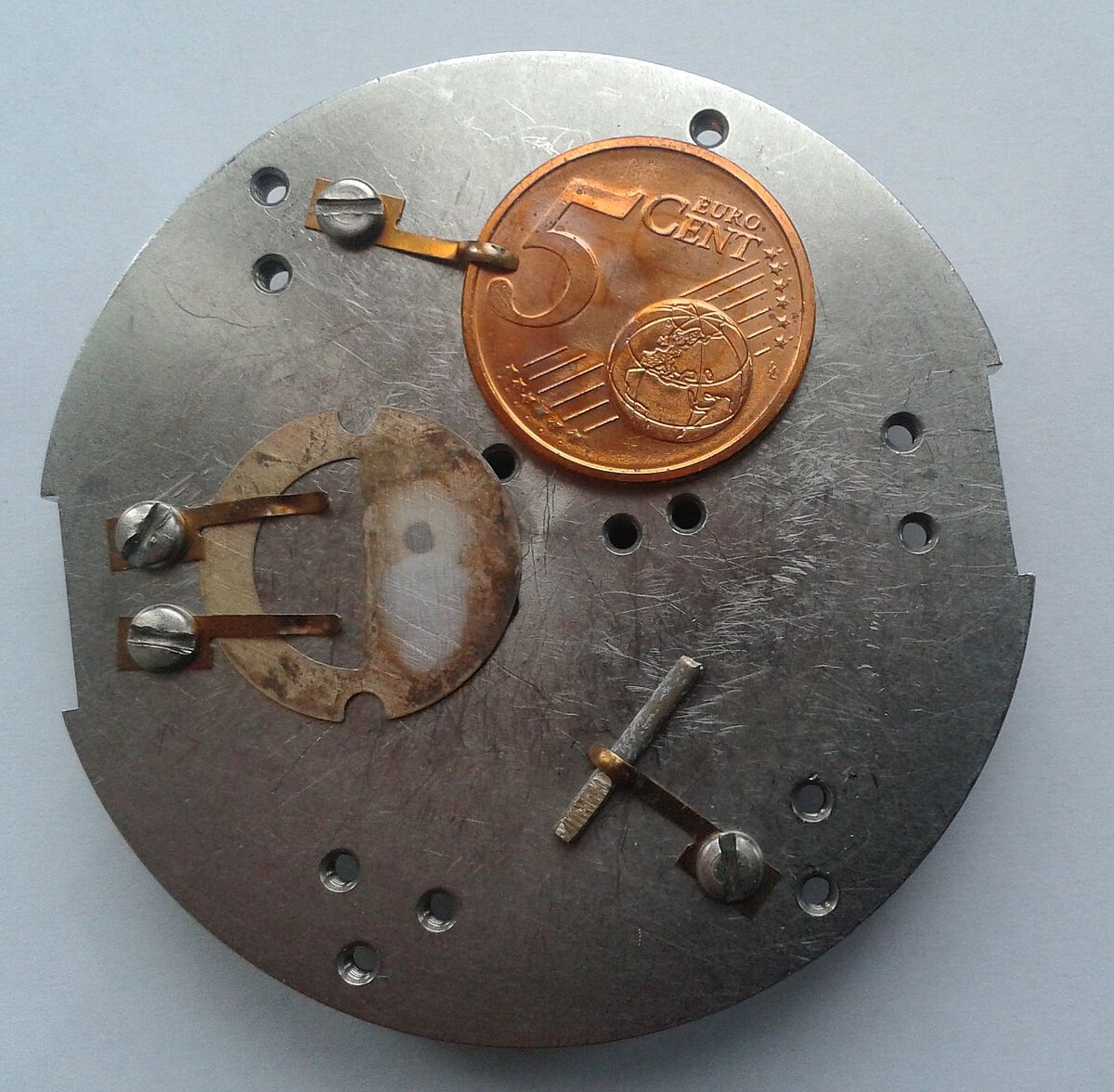

Sample Size

- 10 x 10 mm² sufficient (analysis area 0.8 x 2 mm²)

- Maximum size 50 x 50 mm² lateral, 10 mm height

Sample Holder

under construction